Working in the machine vision industry for 28 years, I am still amazed by how vast the world of 3D scanning really is and the untapped potential this technology has to offer. With technical advancements in 3D scanning and the adoption of consumer-based 3D scanners on the rise, the industry continues to evolve.

3D Inspection for Quality Control

When I joined LMI Technologies in 2003, our laser-based 3D sensors were mainly used for 3D inspection applications in industrial environments for quality control. There are many machines, processes, and assemblies that affect the quality of a final product. Having an inspection solution in place ensures that consistent product quality levels are met and free of detects, whether it is manufacturing products on an assembly line or measuring roads to ensure the surface quality is according to transportation standards. For quality control, especially in automated in-line inspection, the need for both speed and precision measurements is essential. While 2D measurement systems gradually replaced manual inspection for quality control during my time as a computer scientist writing code, the demand for 3D inspection and its value has taken hold. 3D inspection is essentially quality control based on the use of 3D data captured by 3D sensors as a part moves through a production process. The 3D inspection process ensures manufactured parts meet specification. 3D overcomes many of the downfalls of applying 2D machine vision and is a better methodology overall. I have presented this case in my presentation at the Vision Show in the following video.

As 3D technologies can be perceived as complex and expensive, we at LMI felt compelled to create a 3D inspection solution that focused on the user experience–simplifying the technology and enabling solutions for use by process engineers and not just for machine vision specialists. This led to the Gocator 3D smart sensor product line where in 2010 we achieved a big step by releasing a truly smart series of inspection products that offered these benefits:

Ease of use: While conventional inspection systems are often complex, difficult to setup, and require special PC software applications, 3D inspection solutions like the Gocator makes setup simple with a built-in web server user interface experience offering responsive and intuitive interaction. Just connect a web browser–it’s a beautiful thing!

Smart capabilities: With measuring algorithms integrated into the sensor, 3D measurement and control decisions (sorting, pass/fail, alerts) are made within the device.

Pre-calibrated optical assembly: The device is ready to produce 3D measurements right out of the box with a simple setup.

As a result of having these features, the Gocator enables easier setup and integration of an inspection solution into manufacturing facilities by process engineers. The benefits of 3D can finally be deployed by process technology people in the factories where part inspection is needed.

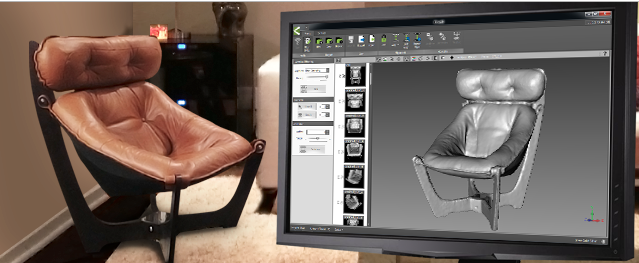

3D Scanning that Focuses on Obtaining Accurate, High-Resolution 3D Models

With LMI’s acquisition of 3D3 Solutions last May 2013, I was immersed into a different side of 3D scanning markets and opportunities. The focus in these markets is on producing accurate, high-resolution 3D models that enable many downstream processes. 3D scanners are used to capture shape and surface texture from a real-world object. In order to produce these models, the scanner is powered by 3D scanning software that runs on a computer. This is very different to the scan-measure-control sequence used on moving parts we solved with the Gocator that doesn’t use a computer. This was more like a scan-stitch-combine approach.

There are various types of scanners in the market. 3D scanners like the HDI series require the object to remain stationary during the scanning process. These types of scanners can quickly scan an object in less than a second and produce dense 3D point clouds. With larger objects, handheld scanners are used much like a smart phone is used to sweep a scene while scanning and stitching to build a panorama photo. Each type of scanner has their strength and weakness. Selecting the right scanner for you depends on your application and your scanning requirements.

Creating accurate, high-resolution digital 3D models from real-world objects is useful in various industries and in numerous applications. Here are some examples:

Medical Applications: 3D scanners have the ability to capture 3D measurements of faces and bodies in seconds. With these measurements, the creation of customized medical products (such as foot orthotics, sleep apnea masks, and scanning of dental molds to create braces, retainers, and mouth guards for patients) is much more accessible to medical practitioners.

3D Modeling: The ability to recreate real-world objects and humans in 3D form makes it an attractive option for gaming, animation, and the entertainment industry for CGI (Computer-Generated Imagery).

Reverse Engineering: Product designers and engineers can quickly and accurately reproduce a physical model, take precise measurements, and then create a mating part or improve on the product design.

Quality Inspection: The ability to capture complex shapes with precision makes it an ideal solution for quality control where a manufactured part can be compared to a golden standard or to the design intent of a CAD model.

Archiving the past: Archaeology handles the preservation of objects such as sculptures and fossils. 3D scanners can capture the measurements of an object without causing disturbance to the original.

New Wave of 3D Scanning

Previously, 3D scanning devices were very expensive and were mainly reserved for businesses that had the budgets to purchase them. However, the trend over the past few years has moved in the direction of “democratizing 3D” where very affordable 3D scanning devices are available for the consumer. With the rise of low cost 3D printing, there is a growing demand for low cost 3D scanners that can acquire 3D scan data to drive 3D printing. These low cost solutions ($400-$1500) range from desktop 3D scanners like the MakerBot Digitizer 3D scanner to 3D Systems’ Sense handheld 3D scanner. At LMI, we also offer a consumer-based 3D scanning software called KScan3D that connects directly to a Microsoft Kinect or Xtion sensor to create 3D models in minutes. While these consumer-based options are less expensive than ones used in industrial or commercial applications, the quality of the 3D scan data is considerably lower compared to commercial grade 3D scanning devices. These products raise awareness about 3D scanning and its value in future processes.

The use of 3D scanning is an integral part of our lives and occurs without our awareness, whether it is in the movies we watch that have CGI effects or the products we use every day such as your smart phone that were inspected using 3D inspection solutions. The possibilities of 3D scanning and inspection technologies are ever expanding and continuously evolving. I am truly excited in what the future holds!